New robotics deal paves way for innovative industry applications

A new robotics deal is paving the way for innovative industry applications.

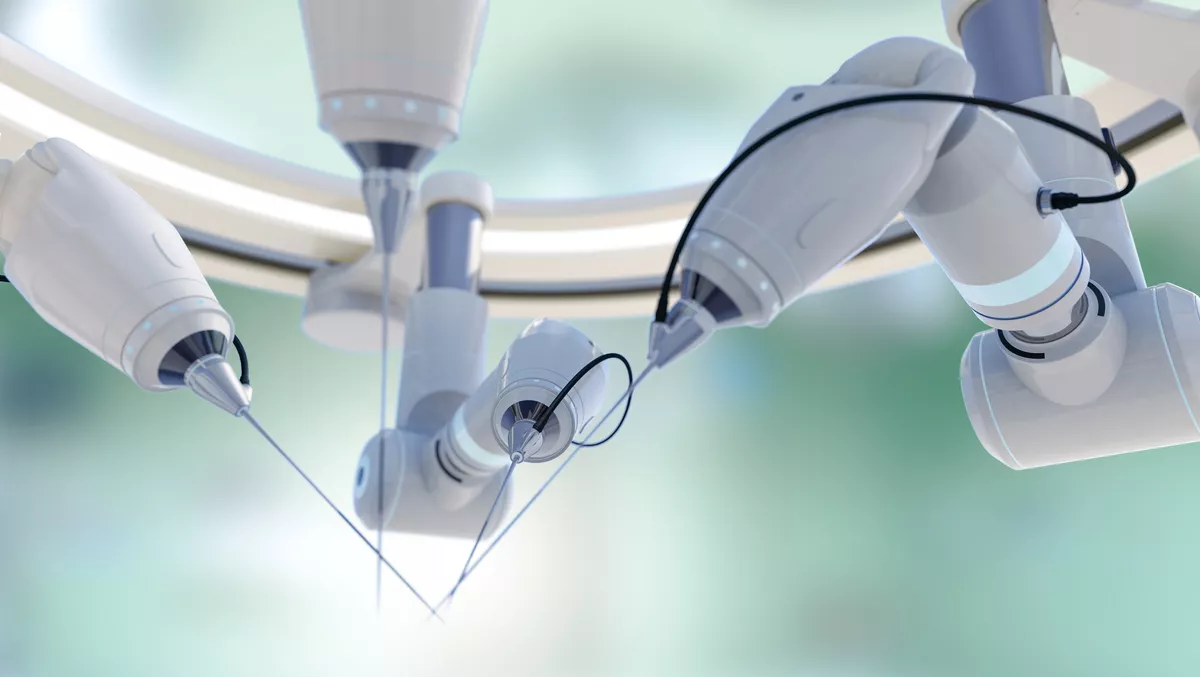

Robotic inspection technology is set to be transformed thanks to an inspection crawler capable of climbing vertically on stainless steel, plastic, glass, and other surfaces that existing magnetic crawlers cannot manage.

A new partnership between global robotics company Nexxis and Invert Robotics will see the new technology, that was originally designed for use in the dairy industry, become available across multiple industries.

Nexxis, which has its headquarters in Perth, also operates in Singapore and Houston. The company specialises in developing tailored robotic solutions to address industry challenges, offering research and development, rapid prototyping and manufacturing, robotic training and support.

Dublin-based Invert Robotics is a commercial technology provider that was spun out of the University of Canterbury's School of Engineering in Christchurch, New Zealand, where the unique suction technology was originally developed.

While robotic inspection technology has existed for some time, most products rely on magnetics to navigate vessels and complex structures where hazards such as confined space entry or working at heights exist.

Magnetic crawlers are commonly integrated with sensor technology for asset integrity inspections in the oil and gas, mining, petrochemical and other industries. In particular, they are gaining popularity to manage hazardous area and confined space inspections of vessels and pipelines.

According to the partnership, the Invert Robotics platforms pave the way for other industries, including food and beverage manufacturers, to carry out inspections in a safer way without the need for plant shutdowns.

Back in 2018, Invert Robotics developed a mobile climbing robot called 'Alfie', that was designed to help to lead the way in workplace safety, particularly for those who work in the chemical, industrial, and energy fields.

The robot, developed in New Zealand, took the technology behind Alfie to Sweden as part of a global challenge.

Invert Robotics was one of 10 companies worldwide to be chosen for further development by AkzoNobel and KPMG.

The robot 'captured the imagination' of the two major multinationals because it is able to investigate confined spaces, which means workers don't have to enter. This can reduce risk to workers and prevent serious injuries or deaths.

"Robotic devices prevent worker injury and death, often caused when workers enter a confined space and are overcome by carbon dioxide asphyxiation or inhalation of other hazardous gases," Invert Robotics' managing director Neil Fletcher said at the time.

"With no need for scaffolding or workers in safety equipment, Invert Robotics now offers its service worldwide in order to reduce this type of serious workplace risk.