Valiant TMS boosts automation efficiency with Realtime Robotics' solution

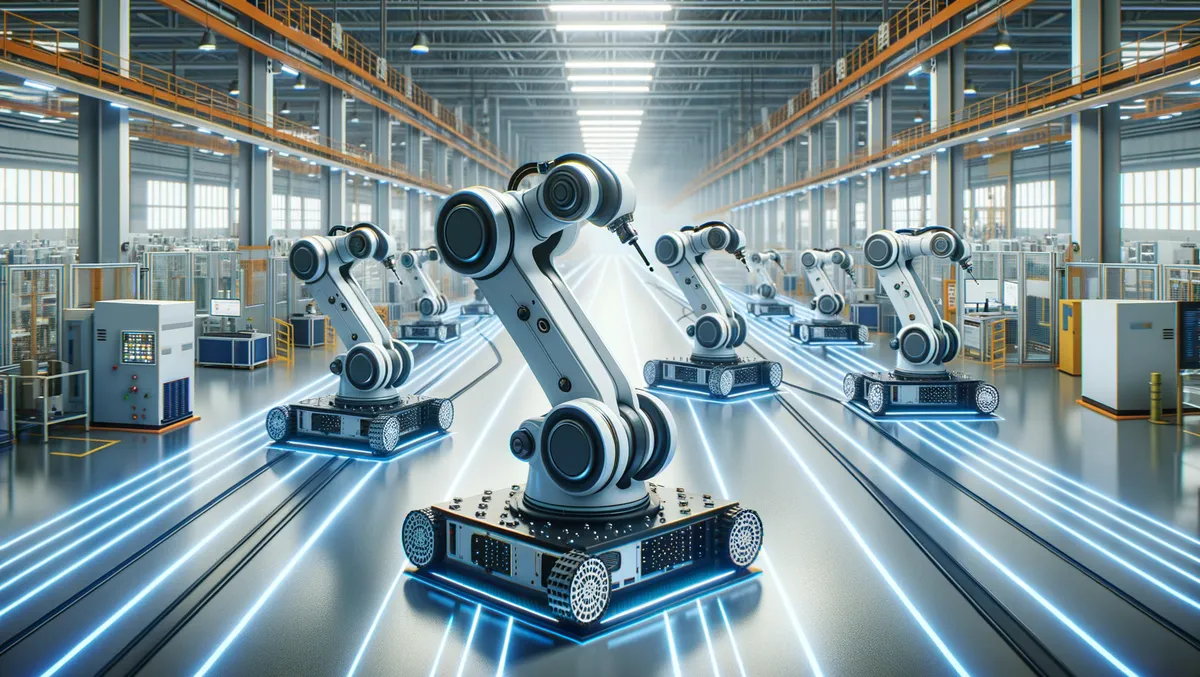

Manufacturing integrator Valiant TMS has chosen to utilise the inventive Optimisation-as-a-Service solution developed by Realtime Robotics. The powerful pairing of Valiant TMS's manufacturing expertise and the proprietary optimisation software offered by Realtime Robotics provides a simplified and effective way to enhance the efficiency and productivity of automation processes.

Realtime's solution swiftly generates and tests hundreds of thousands of possible robot paths, choosing the best motion sequences based on several factors, such as desired target sequences and robot reach. The integration of this technology has resulted in impressive productivity improvements and reductions in cycle time.

For instance, a recent multi-robot application saw Valiant TMS utilise Realtime's optimisation solution in the creation of motion plans. By achieving more efficient motion paths, superior interlocks, and quicker execution times, robot cycle time for a customer was drastically reduced by 17%. Furthermore, robot programming time was halved as a result of the integration of Realtime's solution.

Michael Schaubmayr, Group Manager of Mechanical Engineering Simulation at Valiant TMS, lauded the partnership with Realtime Robotics as trendsetting. He highlighted a remarkable 17% reduction in cycle time compared to manual programming, emphasising its potential to revolutionise automation processes. "The proofed cycle time-reduction of 17% compared with manual programming is breathtaking and will be a game-changer in automation."

For the complete optimisation process to commence, all that is required is a simulation file or digital twin of the cell for improvement. The entire process can be carried out without causing any disruptions to the customer's ongoing production. Once the results are validated, the optimised plan can be transferred to the factory floor for immediate implementation.

Peter Howard, CEO of Realtime Robotics, expressed delight at the industry reception of their optimisation solution. Seeing it as an automated solution to the laborious and time-consuming task of generating potential layouts and paths: "They can reap the benefits without wasting hours of their team's time."

Pawel Kukowa, a Simulation Engineer at Valiant TMS, expressed admiration for the results delivered by Realtime Robotics. "It seems to be the best software among all on the market. Everything indicates that after some improvements, it will be able to eliminate manual work during robot path creation."

Valiant TMS, operating as a full-service Industry 4.0 system integrator, paves the path in digitalisation, process development, design, and technology integration. The company stands out for its expertise in automated assembly, welding, testing, industrial parts washers, and final assembly systems.

Realtime Robotics is a frontrunner in the provision of automatic, collision-free motion planning for industrial robots. Its innovative technology creates optimised motion plans and interlocks to accomplish the shortest possible cycle time in multi-robot cells. The tech empowered by Realtime Robotics expands the potential of automation by enabling robots to collaborate and function together in unstructured environments, reacting instantly to changes.